Cary Usrey

Cary Usrey has been at Predictive Solutions since March 2007. As a Process Improvement Leader, Cary is responsible for implementing best practices for customers seeking to prevent worker injuries. He coaches customers through an assessment, goal-setting, and goal measurement process that is designed to maximize safety improvement and widespread organizational engagement, from the field to leadership. Cary started his career in the U.S. Navy's Nuclear Power Program. After leaving the Navy, he served as the Environmental, Health and Safety Compliance Director at Adirondack Resource Recovery Associates, a waste-to-energy power plant in upstate New York, where he was employed for over twelve years. Following this, Cary took a position with Turner Construction, where he served as the Business Unit Safety Director for the upstate New York office for approximately three years. Cary has graduated with his Associate's Degree in Occupational Safety and Health from Trinidad State Junior College in Colorado, is a member of the Central FL chapter of the ASSE, and has served on the Board of Directors for the VPPPA (Region II).

Publication: ISHN magazine

Publication: Safety + Health magazine

As safety professionals, we want employees to go home as healthy as they came in. As such, we adopt methodologies that aid in incident and injury prevention. Usually, these methods are detailed in a company’s health and safety plan. Follow the plan and nobody gets hurt, right? Suffice it to say ...

Publication: OH&S Magazine

Publication: Safety Decisions Magazine

Publication: Safety at Work Issue: April/May/June 2015

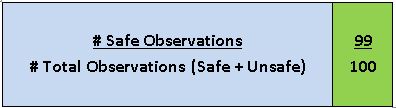

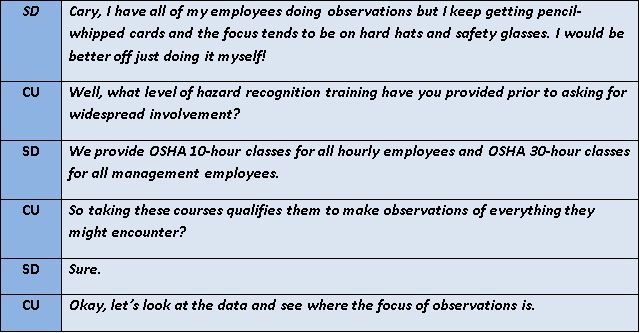

Virtually all companies collect worksite safety observations. Sadly, most companies collect only unsafe findings. This results in a very incomplete picture, as discussed in “The Value of Safety Observations, Especially Safe Observations”. Those companies that do collect safe observations use a ...

Gilbane Building Company uses SafetyNet to integrate its safety risk management program with its insurance provider and reduces its workplace injury rate by 47%. Gilbane Building Company, based in Providence, Rhode Island, is one of the largest privately held real estate development and ...

Recordable incident rate decreased by 76% Lost time injuries decreased by 88% Lost work days decreased by 97% Property damage cases decreased by 22% Challenge From 2006 to 2008 Cummins Rocky Mountain (CRM), a Distributor for Cummins, Inc. with 14 locations and nearly 1,000 employees across nine ...

All employees are openly encouraged to report hazards when they are discovered. In many organizations, this is a basic tenet and often included in the duties and responsibilities of each employee. Some organizations take this one step further and utilize worksite safety observations as an activity ...