Cary Usrey

Cary Usrey has been at Predictive Solutions since March 2007. As a Process Improvement Leader, Cary is responsible for implementing best practices for customers seeking to prevent worker injuries. He coaches customers through an assessment, goal-setting, and goal measurement process that is designed to maximize safety improvement and widespread organizational engagement, from the field to leadership. Cary started his career in the U.S. Navy's Nuclear Power Program. After leaving the Navy, he served as the Environmental, Health and Safety Compliance Director at Adirondack Resource Recovery Associates, a waste-to-energy power plant in upstate New York, where he was employed for over twelve years. Following this, Cary took a position with Turner Construction, where he served as the Business Unit Safety Director for the upstate New York office for approximately three years. Cary has graduated with his Associate's Degree in Occupational Safety and Health from Trinidad State Junior College in Colorado, is a member of the Central FL chapter of the ASSE, and has served on the Board of Directors for the VPPPA (Region II).

In our white paper, Predictive Analytics in Workplace Safety: Four Safety Truths that Reduce Workplace Injuries, we explain a series of leading indicators that allow for the prediction and prevention of injuries. These leading indicators can be derived from two primary metrics:

In our first blog of the series, How to Make the Most out of Your Safety Metrics, we discussed why organizations are shifting their focus from lagging indicators (e.g. recordable and lost-time injuries) to leading indicators (e.g. near-miss reports and worksite observations). While safety experts ...

The safety profession has an unhealthy fixation on measuring using purely negative values. OSHA recordable and lost-time injuries spring to mind – both are lagging, and I would suggest, negative indicators. Once they occur, there is nothing that can be done but to investigate and hopefully learn ...

YOU NEED MORE THAN LIP SERVICE Safety excellence is often whispered in hushed tones, akin to the search for the Holy Grail. Everyone seeks it, and many make finding it their life’s quest. But what is ‘it’?

Introduction Thompson Industrial and Thompson Construction are premier industrial building and maintenance service companies with service locations across the U.S. Combined, the organizations offer industrial cleaning services, electrical construction, pipe fitting & welding, steel erection, ...

In the article “What are Safety Leading Indicators?”, published in National Safety Council’s Safety+Health magazine, a case is made to adopt leading safety indicators instead of relying solely on lagging safety indicators (e.g. injury rates). The reasoning is sound but creating and sustaining ...

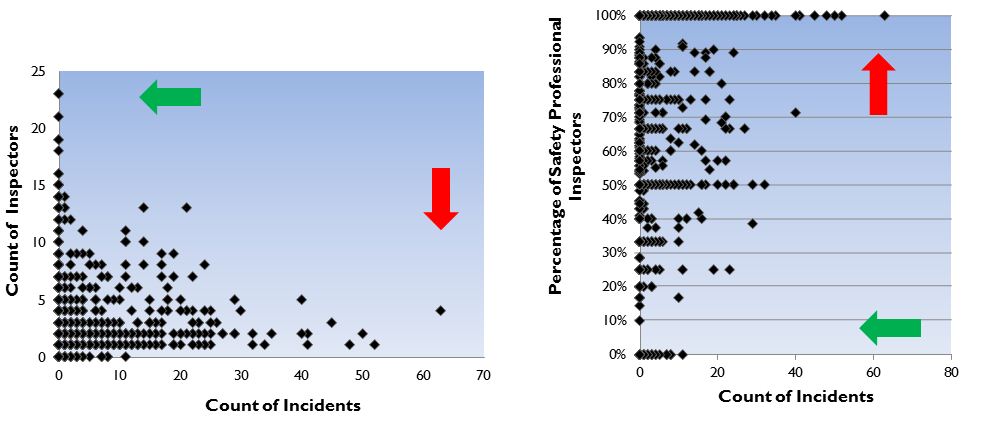

In our last blog article by Dr. Timothy Ludwig, “The Anatomy of Pencil Whipping”, the idea of safety observer quality was introduced. This article, originally published in the VPPPA Leader magazine in 2012, further expands the subject by introducing quantitative measures of observer quality that ...

While implementing a robust and sustainable observation program for companies, one question comes up often: “How many safety inspections should I do?” My answer, of course, is, “It depends.” As cryptic as it may sound, it is true. Safety inspection frequency will depend on several factors:

Most companies conduct periodic worksite safety audits. This process is part of the traditional landscape of a comprehensive health and safety plan. At regular intervals someone within the organization sets out to critically observe in an effort to identify and rectify hazards. Most organizations ...

Work site safety inspections can be a vital part of your injury prevention efforts if done well. Most companies conduct periodic worksite safety inspections. This process is part of the traditional landscape of a comprehensive health and safety plan. At regular intervals, someone within the ...